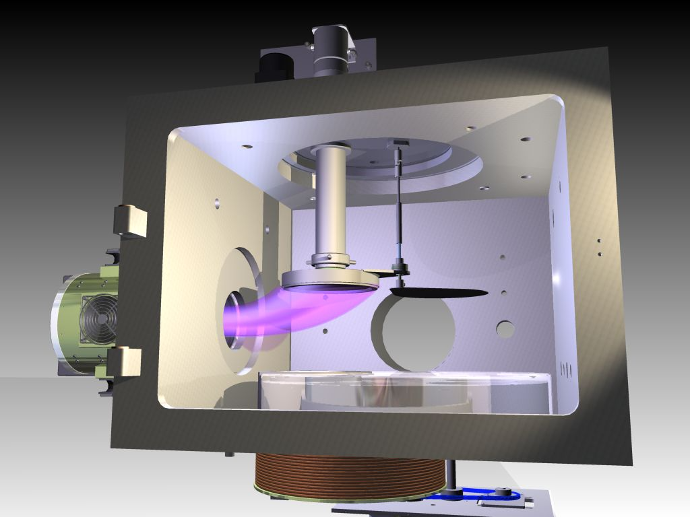

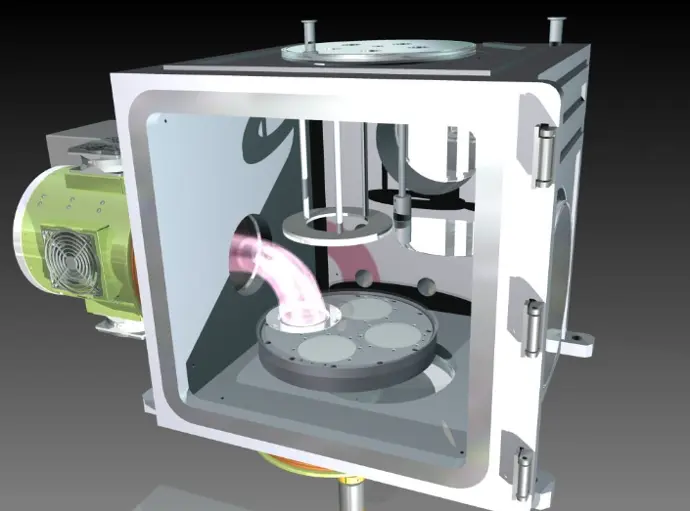

Remote Plasma Differentials

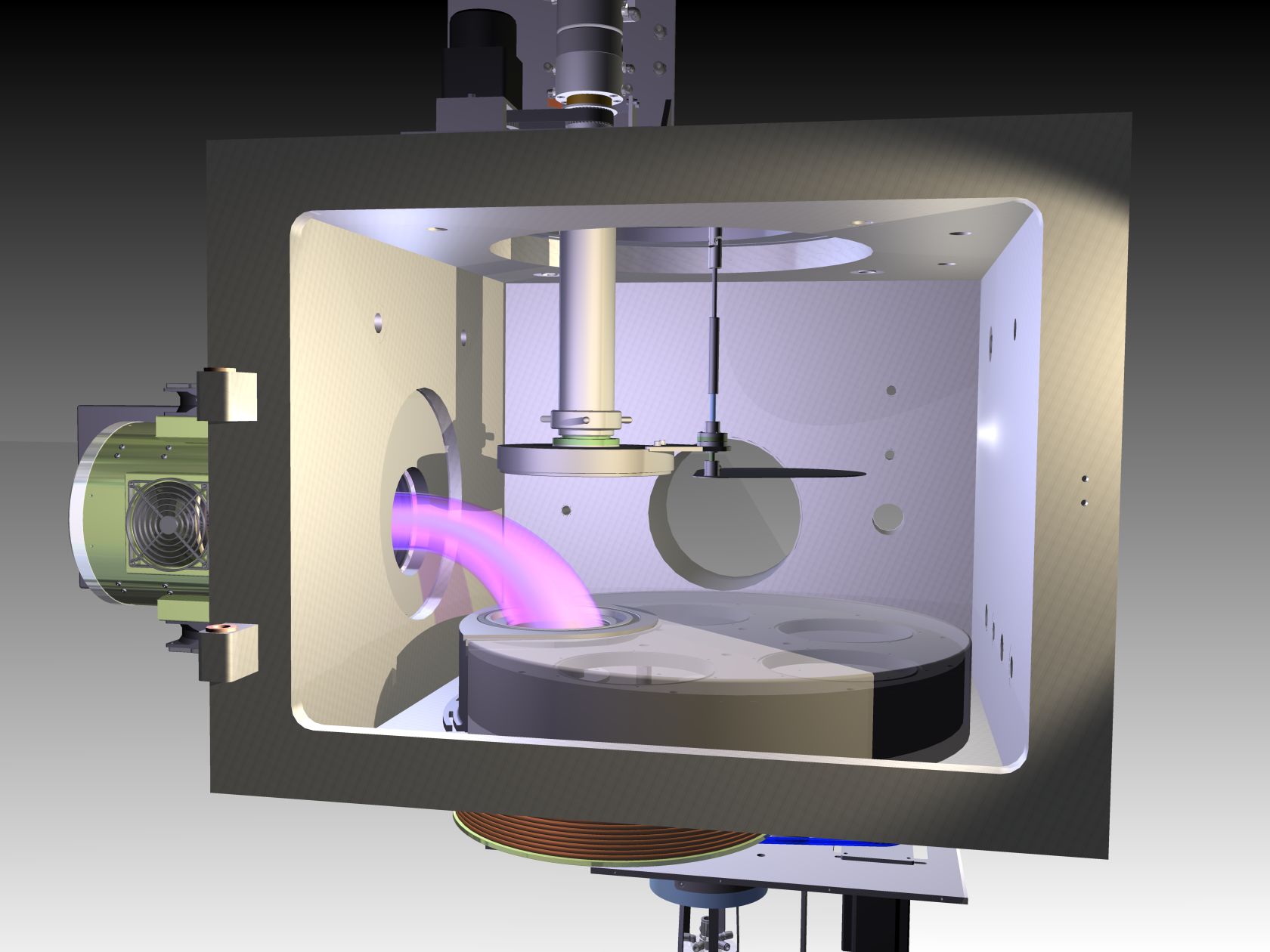

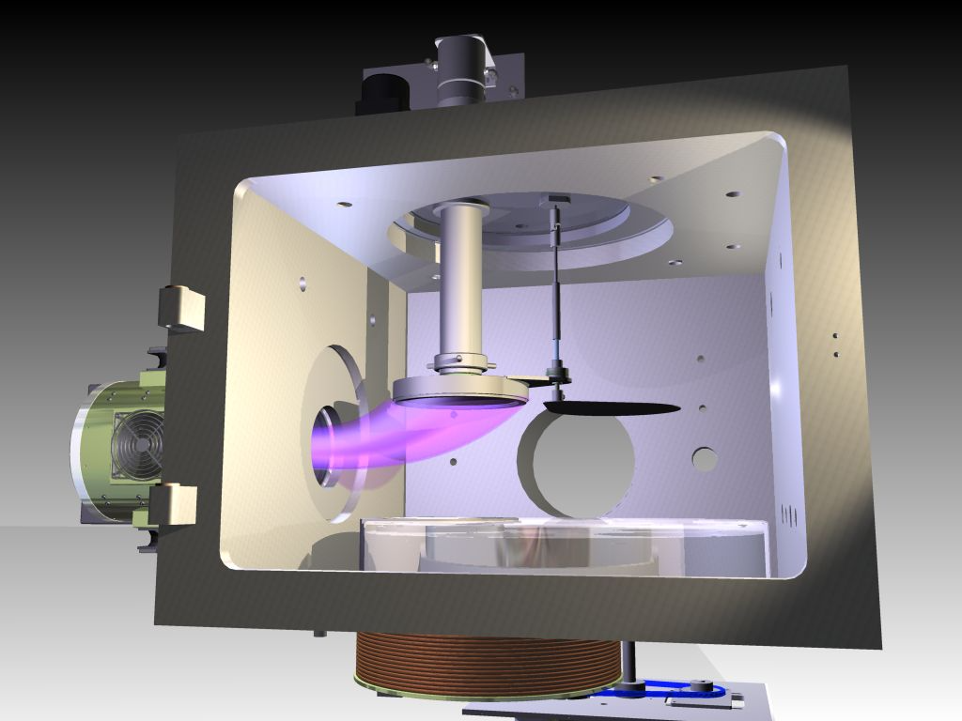

Remotely Generated Plasma enables new coatings on new materials

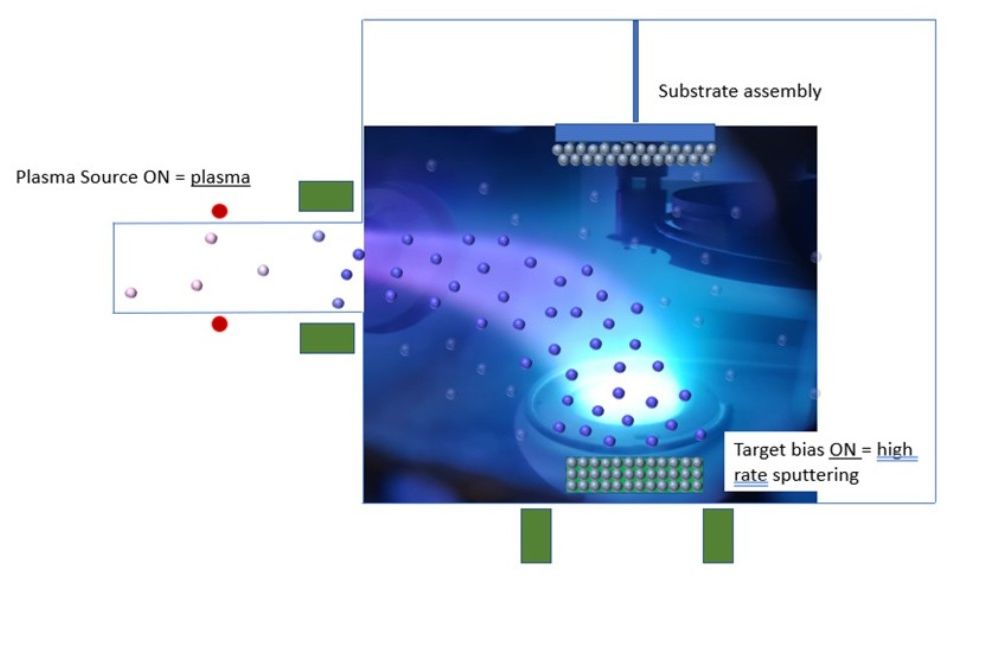

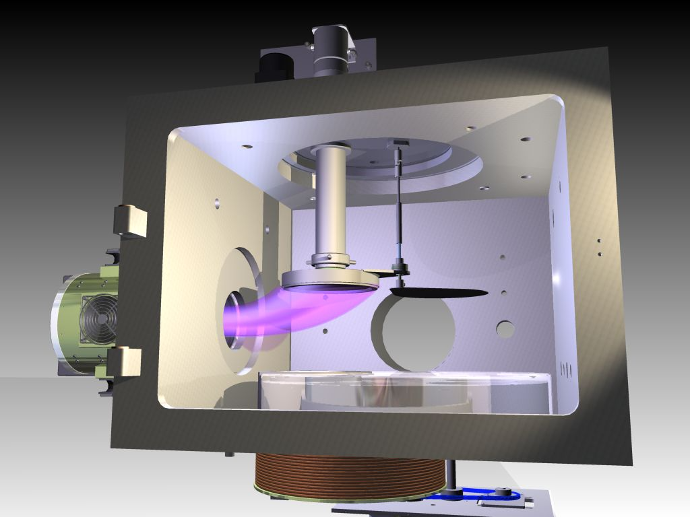

We have independent control of process parameters including target voltage and ion current which enables the deposition of high-quality thin films that can be difficult to produce using other deposition technologies such as magnetron.

Ion density (controlled by Plasma Source RF) and ion energy (controlled by target voltage) are independent.

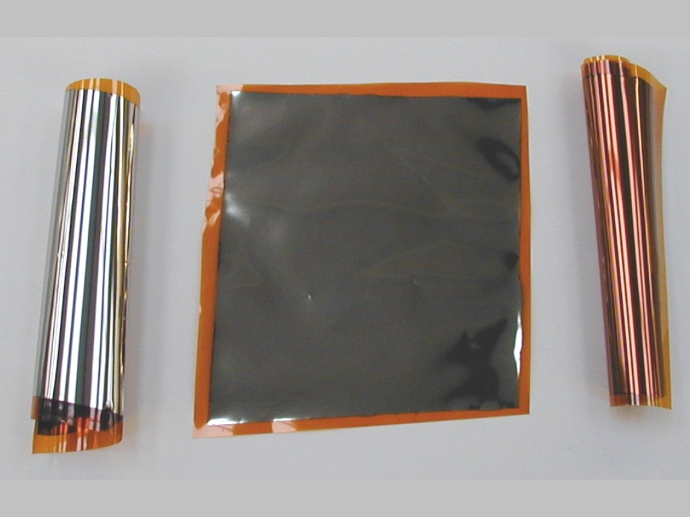

Low Temperature Process

Low temperature deposition onto polymeric and other 'delicate' substrates

The plasma provides energy input to the coating process instead of substrate heating

Deposition onto polymeric substrates; (PEN, PET, BOPP, PES, PMMA etc)

Deposition on to delicate materials (e.g. OLEDs, photoresist, etc)

Very little electron damage; electrons constrained by DC electromagnetic field

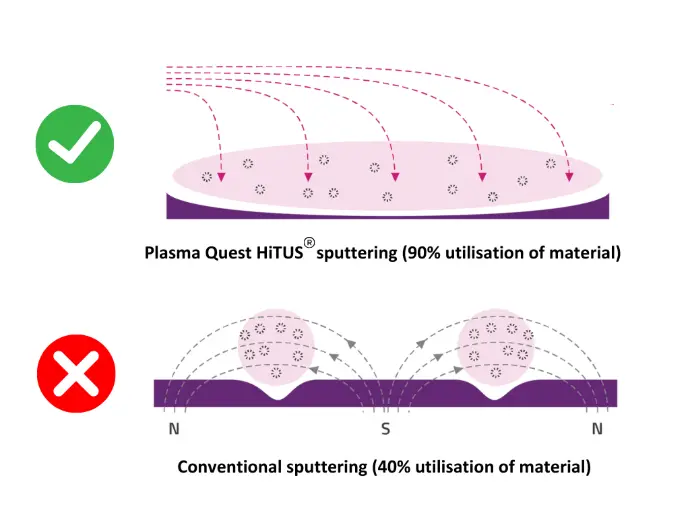

High Target Utilisation

Whole target surface continuously sputters

Stable and repeatable coatings, especially for oxides and nitrides as target is not poisoned

Reduces both costs and waste

No "race-track"

High deposition rates of > 80 nm/min from 4" diameter targets

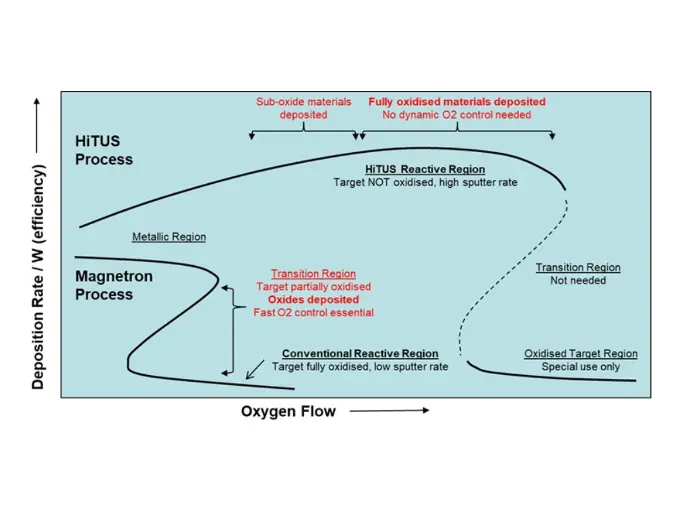

Stable, High-Rate Reactive Process

Remote Plasma offers enhanced deposition rate, process stability & simplicity when compared to conventional sputtering

Reactive processes completed without target poisoning due to uniform surface erosion

No need for feedback control when reactive sputtering

Addition of reactive gas increases deposition rate beyond that of the pure metal

Good control of stoichiometry; enabling deposition of complex materials such as Ti4O7 and Cu4O3

Stress Control

Due to our unique remote plasma process, the technology can be used to control the stress within thin films from compressive through to tensile

In magnetron sputtering the process pressure is varied to control stress

In Remote Plasma Sputtering the stress is controlled by process pressure and target voltage - extra process parameters to control stress

Thick Ferromagnetic Targets

No magnets directly behind the target.

Ability to sputter from thick ferromagnetic targets: less system downtime

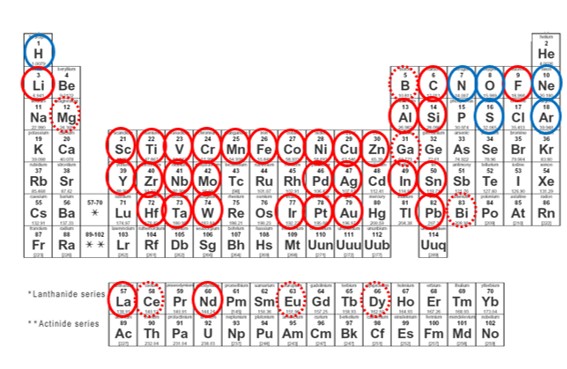

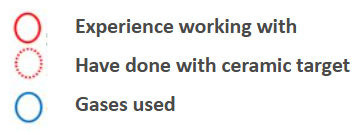

Materials we have experience depositing:

- Fe, Co, Ni, CoFe, NiFe, Inconel, NdFeB

We have achieved stress free thick ferromagnetic coatings with good adhesion

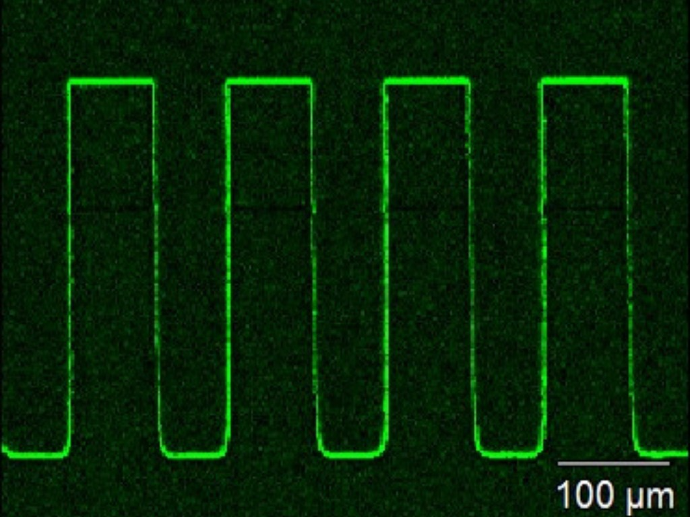

Ionised Physical Vapour Deposition

The high density plasma can ionise a significant fraction of the sputter flux

With an electrically biased substrate it can influence the directionality and energy of the arriving ionised material

Enables conformal coverage of high aspect ratio substrates and other complex topographies

Image shows an EDX map demonstrating that the RF substrate bias can be tuned to produce a uniform and conformal coating of thin film Al2O3

High Adhesion of Coating

Can immerse substrates in high density plasma prior to deposition to help promote good adhesion

Plasma assist improves adhesion, often eliminating the need for tie interlayers

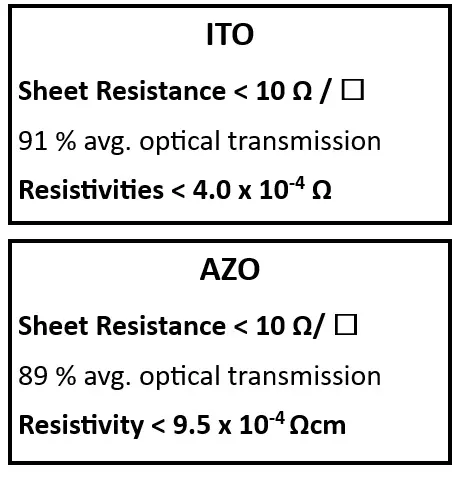

Wide Range of Materials

Metals, magnetic materials, TCOs, dielectrics, polymers

Periodic table opposite highlighting the materials we have experience with. Remote Plasma Sputtering could potentially be used to deposit those materials not highlighted but, to date, these have not been attempted

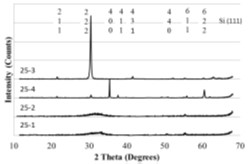

Control of Crystallinity

Films can be deposited with an amorphous or crystalline structure by controlling the plasma energy during growth

Image shows the effect of increasing plasma source power for an ITO coating

Substrate Plasma-Treatment

The Remote Plasma nature of the process means that inherently the system enables the substrate to be plasma treated;

This can be done with a number of gases

Offers enhanced adhesion performance

Plasma Quest developed a unique plasma treatment during a government funded program (InREP) that enabled an ohmic contact to be achieved between our AZO coatings and the doped GaN substrate

Substrate etching

With substrate bias, uniform etching of the wafer can be achieved